Frank traveled to Kumasi, Ghana and helped a team there set up a small sorting and roasting facility for Project Peanut Butter, a non-profit that makes Ready to Use Therapeutic Food (RUTF)

The facility needed:

Cleaning, blanching, white roasting and sorting equipment, which was installed in the Kumasi facility.

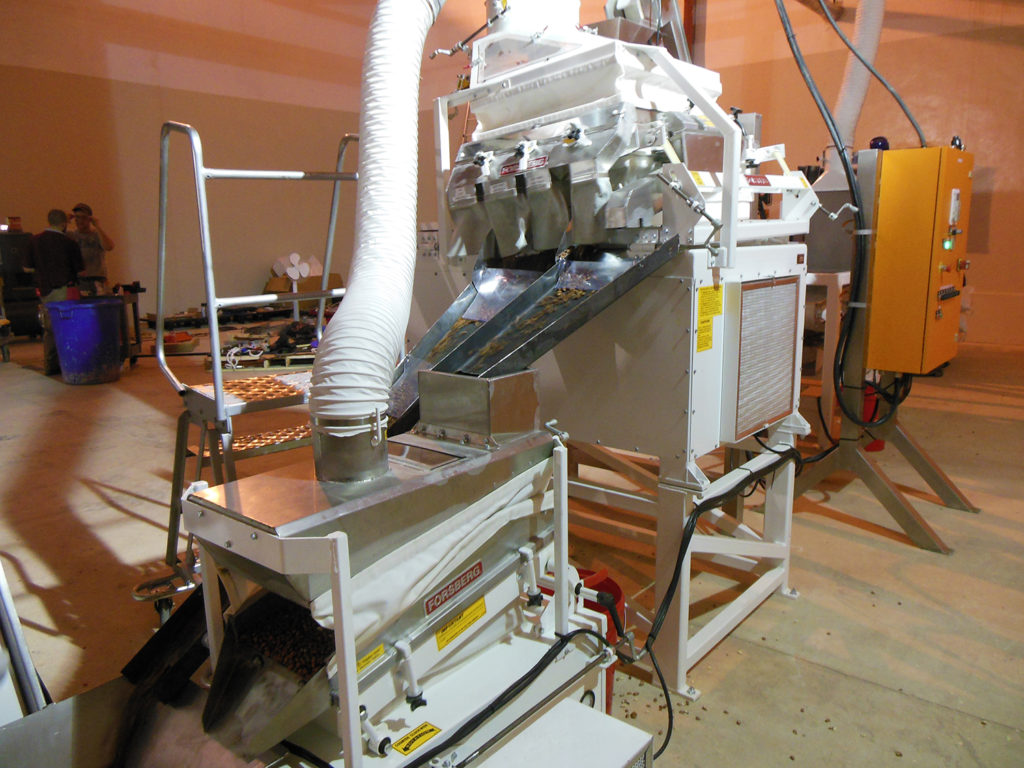

Gravity table and destoner separates debris from the nuts and begins to sort by density.

A sizing shaker sorts nuts by size.

This double spliter/blancher is used to split kernels and remove the skins. This process is done after the nuts have been white roasted or dried down to between 4.5% and 5% moisture. This process exposes any inner damage in nuts, which can then be sorted out, reducing the chance that nuts high in aflatoxin remain in the batch.